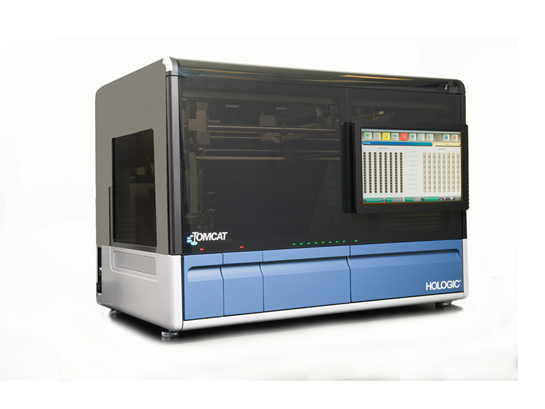

Services Provided:

Concept development, hardware design, software design, user interface, prototyping, supply chain development, verification testing, value engineering, New Product Introduction, safety certification, manufacturing, after-market services, current product engineering

Key Technologies:

- Dual XYZ Gantry robots nested together in a compact form factor

- Pick-and-Place Robot – Manages transport of multiple tube types at speeds up to 50 ips over 30” of travel

- Pipettor Robot – Manages aspiration and dispense between reagent, patient sample and output vials

- High speed, high precision XYZ coordinated motion

- Integrated compact vortexing and de/capping processing module

Distributed motion control topology – custom control boards through CAN bus interface - Tube barcode printing module integrated into patient workflow

- Master controller SW, modular motor and system embedded controller FW developed under ISO 13485 controls

- Used client’s design procedures to comply with Class II IVD and IE 61010

Business Outcomes:

Successfully developed a complex system automating patient sample preparation workflows with process controls that delivered on the client’s business goals of high throughput and reliability for increasing the usage of their clinical diagnostic equipment